Induction Heating

Salesman to Entrepreneur

On his way out President Eisenhower warned that there was a potential for a disastrous misplaced power of a "military industrial complex".

On February 1, 1961 the US launched the its first solid-fuel rocket named the "Minuteman". One month later the X-15 reached an altitude of 31 miles and a speed of 2650 miles an hour.

The sixties were not going to be calm, but I had a new job and was very excited. Our family of six moved to Yardley Pennsylvania just a few blocks from the house where Rowan lived in the 40's.

Ajax Magnethermic hired me as project salesman on April 1, 1961. Two weeks later the Soviets put Major Yuri Gagarin into space to orbit the earth in 89.1 minutes. Two weeks later there was a failed attempt to overthrow Fidel Castro's Cuba at the Bay of Pigs. One month later Navy Commander Alan B. Shepard entered space in Freedom 7 propelled by a Redstone rocket. Twenty days later President Kennedy asked congress for $9 billion to send an American to the moon. The space race was on.

This was the beginning of the end of Soviet style communism. The ultimate victory was the development of the transistor that America needed because the Soviets were ahead in space lifting power. This would lead to lightweight and accurate payloads for space but most of all to increased productivity of the information age. It is ironical that Soviet academics led the way to microcircuit technology in the late 30's but did not know what to do with it.

Inductotherm and Rowan were now my competitors, and knowing how they sold was useful in setting up the battle plan. Ajax had been set in their ways. While they were the leaders in the industry, they cut a few costs by using five small meters on their control panel. Every Inductotherm quotation opened with "Six large face instruments." It was easy to convince the new management at Ajax to use six instruments to take that item off the table.

Ajax was using a capacitor contactor purchased from Allen Bradley that was expensive and was causing problems because the higher frequencies overloaded it. Inductotherm had a rugged contactor they built in their plant. I suggested that Ajax purchase one of these contactors and find cost effective way to produce it to take that item of cost off the table.

Rowan was leasing his equipment to improve sales. Logan had plans to become a public company and the idea of leasing crossed his mind. His accountant noted that this would increase his long-term debt on the balance sheets. The accountant made an agreement with General Electric finance so we could lease equipment.

Inductotherm were locked in with Westinghouse horizontal generators that they purchased in quantity. Logan had entered into a contract with a generator manufacture to build a vertical generator. To cover the cost of design and tooling he ordered the sales departments to pass on $1000 per generator sales to the customers. This was fine for the heating division where he had little or no competition but it was a killer in the melting division where Inductotherm was winning the majority of this business on both price and quality. Logan agreed to remove this cost from the melting units.

Rowan was cashing in with his integral unit that combined the generator in the same cabinet. This allowed the customer to place the equipment into service when the power and water was connected. To counter this I suggested that Ajax offer a unit that was both integral but separable.

Logan sued Inductotherm for infringement of his Multiductor patent and the main evidence was the schematic of the Tri-Line Rowan sold me in 1960. I was also aware that Rowan sold another Tri-Line to a new beryllium operation in Yonkers, New York.

My first sales effort for vacuum melting furnaces included a telephone call to Nisbet at Allvac. They were planning to install a five-ton unit soon. Nisbet told me that he would use Inductotherm for the power supply because Rowan was a stockholder and director of the company. He asked me to bid on the mechanical part and I refused. During a sales call to Wyman Gordan I showed a copy of the Multiductor patent in an attempt to win the business.

Both of the events were included in a counter-suit for restraint of trade filed by Rowan. Later all the suits were dropped and Rowan won a major victory when he agreed to pay a license fee on units that featured a choke. At the time he knew he could build a choke feature into the encapsulated transformer that he learned to build from Hunterdon. This simple victory became the most important event in the history of the profitability and future of Inductotherm.

On August 7, 1961 Cosmonaut Gherman S. Titov orbited the earth seventeen times in Vostok II. Later in the month Berlin was cut in two by the Berlin Wall. NATO troops were placed on full alert and it appeared for a time that a shooting war would begin. History records a face to face meeting of Russian and American tanks at checkpoint "Charlie." Finally the Russian tanks backed up three feet and the Americans backed up ten feet. It is a pity we did not have CNN in those days. Stalin was removed from Lenin's tomb is disgrace for his purges of the 30's and 40's.

My first victory over Inductotherm in the field of vacuum melting was at Firth Sterling, a small steel company in Pittsburgh. Inductotherm was still trying to sell motor generators so Ajax with its Multiductor and my practical knowledge of how a furnace should be loaded and unloaded won the job. The nail in the coffin was that Rowan was a shareholder and director of their competitor Allvac.

Ajax did not have a design staff to complete the vacuum portion of the project, so it was time to move Joe Lona out of Hazleton. The promise of overtime payments and his wife's desire to get out of the strip mine area was all we needed to convince him to come. He could see the handwriting on the wall and knew that the factory in Hazleton would close soon because beryllium was being replaced by simple fiberglass composites for the structural parts of new rockets. I really needed Lona because he understood that my selling ideas were not always workable and that I was a neophyte when it came to mechanical designs. The Firth Sterling job was the beginning of the end for my future competitor, Stokes, because it was built very cheaply and effectively.

My next sales victory was at Westinghouse. Inductotherm bought all their generators from Westinghouse and I was facing an uphill battle. These furnaces were being purchased using government money for their nuclear division using open bids. I won that job fair and square with the lowest bid and better technology. Rowan very angry when the public bids were opened.

This was the first time carbon felt was used for thermal insulation. Up to this point carbon black had been used as high temperature insulation in graphite furnaces.

The military budgets in America and the Soviet Union were increases dramatically. Kennedy's Secretary of Defense announced a new MAD (mutually assured destruction) policy. The name and the policy sounded absurd to me, but the expensive policy worked. It will cost future generations untold billions to unravel and clean up this mess.

During the start up phase of the Firth Sterling I met Mr. Hopkins who was credited with the first use of the electroslag melting process in the USA. The simple equipment they purchased made a casting that was 8 inch round by 10 foot long. Hopkins told me this was an electrode or big welding rod. He showed me his monster welding machine that melted the electrode into a 16 inch round copper water cooled mold by 10 foot long. The process started by pouring a liquid mixture slag into the bottom of the mold before he struck the arc to start the melt. When the first ingot was melted he started another until four were consumed to fill the mold. The slag protected the metal from oxidation and the slow cooling process produced a fine grain product that could be forged. (ESR)

I thought this just might work for the metal beryllium. Hopkins told me that these reactive alloys would be easier to produce by the same welding rod process but with the cooling mold under vacuum. He told me that a new jet age alloy of relatively pure titanium was being produced in vacuum consumable arc equipment. (VAR)

Hopkins showed me a modified sixteen-inch cannon that they were using to press tungsten carbide into finished shapes using oil under very high pressure. This equipment was called an isopress because pressure was equal from all sides. On display was the shape of a hand that was produced by filling a rubber glove with metal powder and closing it before pressure was applied.

I took the idea of vacuum arc melting (VAR) to Ajax management but they told me that our plate was full and Rowan had just announced that a new firm had been formed to supply this type equipment called Consarc. (Acronym for Consumable Electrode)

Our third daughter, Patricia, was born in Trenton, New Jersey. We lived in a large house in a good section of Levittown, Pennsylvania. Levitt and Sons built this little city after the war. This town was a masterpiece by any standard of architecture. A large area was leveled to construct the new city that included schools, churches, parks, trees, flowers, shrubs streets, underground power, underground telephone cables, shopping centers and homes arranged in parks with names at different price levels. The homes were complete with modern appliances.

The sales group that sold these homes before they were constructed promised that only whites could buy. The civil rights movement of the sixties corrected this injustice just before we moved into this area. The words that Martin Luther King spoke made me shiver. This man was standing on the moral high ground. Hoover was already chasing him as a Communist.

The Voice of America and Radio Liberty were winning a wide audience in the USSR by playing Elvis Presley music, while mixing in the message of freedom. But America was losing the propaganda war because freedom had to cover all people including the blacks. Moscow was reaching out to Africa and bringing in enough black people to capture a positive position in the world press and with the Soviet people. Kennedy was afraid to support the civil rights movement because he might lose the election in the South.

My first ride on a jet airplane was from Newark to Boston. The Eastern Airlines jet felt like it was going straight up shortly after take off. The customer was Raytheon and they wanted equipment for production of a material called pyrolytic graphite. Ajax lost this order due to lack of experience while Inductotherm was able to obtain all the pyrolitic graphite equipment business at SuperTemp, Hitco, and Pfizer.

To increase sales SuperTemp made a pipe from pyrolitic graphite that they marketed under the trade name, "The Pipe." The process required heat of 5000 degrees F. and a mechanical vacuum pump so natural gas could flow through the hot zone. Under vacuum carbon is stripped from methane and deposited in very thin layers. In one direction the resultant carbon product was a very good insulator and in the other direction it was a good conductor.

A short film shown on TV in those times demonstrated this with an ice cube. Using a flame it was demonstrated that ice quickly melted on top of the material and remained ice at the end of the material.

When the export control regulations were issued in 1979 equipment for the production of pyrolitic graphite was listed as requiring an export license.

Apparently some nuclear or military component was made with this material. More than 150 years earlier this product was produced as "glance" coal in the upper parts of the retorts that produced water gas.

A new beryllium operation opened up in Gaston County, North Carolina. They needed a melting furnace and a small hot press. Lona and I were able to close this order without any trouble. When it became time for the start up we loaded the helium mass spectrometer that was designed to be a leak dector in my minivan and drove nonstop for eleven hours. When we checked into the motel we found that we were in a dry county and could not buy a cold beer. The local management took us to the American Legion where the bar was fully open. That night everything was free because a raid was planned for the next day.

During testing of the vacuum chamber we found that the eight-foot door was out of flat and the "O" ring would not seal. Lona constructed two large door clamps that required a long bar to clamp the door. With a straight face I explained to the customer that this was normal.

A very important sale was for a five ton vacuum melting facility for processing superalloy to Carpenter Steel in Reading, Pennsylvania. Rowan had developed his Tri-Line power supply unit by that time, but his people made the mistake of allowing Carpenter Steel to believe that the whole idea for the trippler was theirs from the beginning. After that was set straight I won the job with ease. In those days, steel companies liked furnaces that were simple to use. I used most of the ideas from the Firth Sterling job, only larger this time. The real breakthrough was to use an oil filled transformer made by a transformer company instead of the homemade stacks of iron and water cooled copper Ajax was using at that time. The final blow was that Rowan was a director of their competitor.

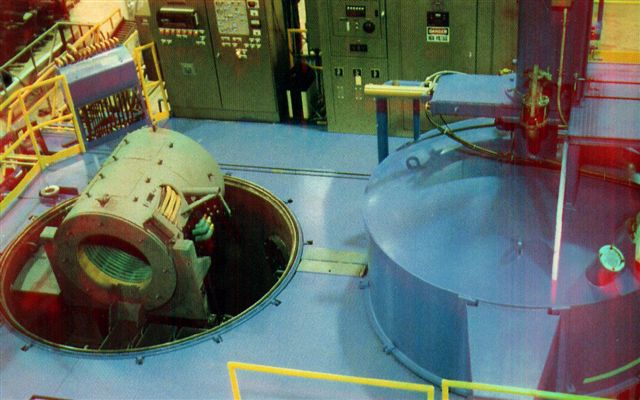

Carpenter already had a Stokes/TOCCO furnace that they purchased in the 50's. Carpenter was already melting titanium using the vacuum arc melting process using equipment supplied by Electromelt. Titanium alloy had been perfected by this time as a major player in the jet engine. Titanium was reduced from the chloride using magnesium to a sponge like material. The sponge was then pressed into a billet and melted in a vacuum arc furnace to produce a rough ingot. This ingot was melted again in a vacuum arc furnace to produce a billet that could be forged into parts.

The vacuum arc equipment was similar to a very large welding machine with a DC power supply at about 15-volts that was rectified to a direct current at about 10,000 amperes. The welding rod was a 14-inch billet of titanium and the welding arc in vacuum was contained in a water-cooled copper crucible where the liquid metal froze to form the ingot. Molten titanium and water form a violent reaction if mixed and many designs to get around this problem were attempted in the early days.

The main reason Carpenter wanted the vacuum melting furnace was to produce electrodes that could be remelted in the consumable furnaces. The Irish owner of Consarc, J Wooding, made permanent enemies with the managers when he told them that a black box on the table held secret new features of his equipment. He would open the box if they gave him an order in advance.

On February 26, 1962 Lt. Col. John H. Glenn orbited the earth three times. Later that year the Soviets orbited the earth with two spaceships in tandem.

The Cuban Missile crisis ended when the Soviets withdrew their missiles from Cuba on October 28, 1962 when the US agreed to remove missiles from Turkey and quietly agreed never to invade Cuba. On November 27 Boeing introduced the Trijet as a 727. The need for vacuum metal would soon increase to produce this fleet.

In 1962 Ajax sent me to NASA headquarters to meet a room full of high-priced engineers who were working on a project to use high-pressure super hot hydrogen. http://www.ioa.com/~zero/392-AjaxNASA.html

In June 1963 Kennedy visited the Berlin Wall and uttered his famous sound bite. "I am a Berliner" A few days earlier the Soviets sent, Valentina Tereshkova, the first woman to space for eighteen orbits.

The management of Ajax decided to move the company to Warren, Ohio. The announcement came as a shock to the employees and their families. Many people refused to be transplanted to the Midwest.

We bought a house that was just across from a private airport. The airport property was worth millions to the real estate developers, but the seventy-two year old owner preferred to operate his small pilot training operation. The site had two long grass runways side by side. His method of training was to teach only take-off and landing in his Piper Cubs with no instruments. He taught me how to lift off before make a full left turn at about one hundred feet and line up with the other runway for landing. After five lessons at three dollars each I flew solo.

Rowan had his pick of engineers that did not want to move to Ohio. Jim Huff and Al Coley brought Rowan the channel furnace business from Ajax Engineering to set up a partnership division that they named Linemelt. This time Rowan owned 52% with Huff and his employees owning 48%. Not only did Huff bring Inductotherm an important part of the Ajax business in channel furnaces he brought the designs for steel shell furnaces used in the 60-cycle melting furnaces. Rowan was able to use this technology for new vacuum melting furnaces. A thirty ton furnace was sold to Latrobe Steel and sometime later this unit was duplicated at Kobe Steel in Japan. From the Huff technology a 90-ton shell and coil was designed and built for Cameron Iron in Texas.

Somehow the Linemelt operation was consolidated into Inductotherm without paying Huff for his fair share of the profits he brought with the root technology. Before he retired Huff told me he felt cheated but had lived a satisfying life in New Jersey.

Logan had expected a surge in profits as the result of moving the melting divisions from New Jersey and putting them under on roof with his successful induction heating product lines.

Like mixing oil with water the New Jersey crew were not effective and labor problems in Ohio would allow Rowan to leap frog past Logan in a few short years.

Union Carbide ordered a furnace for the continuous heat treatment of carbon cloth.

President Johnson was our president and he had to prepare for his upcoming election. He announced the Great Society program that included a little something for everybody and pledged to pass the civil rights act.

The move to Ohio took time and soon it was clear that Ajax did not have enough engineering staff to complete the NASA job. Logan asked me to move from sales to engineering to take over the high frequency melting department under Sid Sedgeworth.

On August 7, 1964 we faked the Gulf of Tonkin incident to obtain legal authority to start the Vietnam War. On October 16,1964 China exploded an atomic bomb and the Soviets had a good reason to continue to arm themselves and set up a missile defense just as Brezhnev was taking power.

The Goldwater campaign was tough on communism but as a nation we could not find the moral authority to spend money on war. Johnson won easily and did sign the civil rights bill.

I felt trapped again. It was impossible for me to work with the details, and to be honest, I did not have the ability. A new Beryllium operation had been started in North Carolina and their manager quit. Beryllium was dying as a material of the space age, but I could not be a designer, and it was going home time again.

My first day on the new job was a shock. Scrap pieces of the secret parts we made for the Polaris and atomic explosive part of the missile were in the open scrap market. I called the FBI and after a short investigation they told me that the government was not concerned. The price of this scrap was five times less than the cost of producing the metal from the oxide. This company owned the mining rights to Kings Mountain and the very basis of this project was to produce Beryllium from the minerals on this mountain.

I called Lona to complain that the door the vacuum chamber and he reminded me that I had already told myself it was normal to use a long pipe to make the door clamps work.

The Pentagon was still buying these obsolete items that would never be used. There was time for a quick profit if I moved fast. I called Rowan at Inductotherm to find a power supply that would be in stock. At first he did not want to talk with me. He soon realized I was again a customer. I gave him an order and the equipment was shipped that day. I called the scrap dealer and placed an order for all the beryllium he had in stock. A few weeks later the price was up six-fold. There was some price-fixing going on.

It soon became apparent that the single power supply for the melting furnace and hot press was going to mean that we had limited production. I needed a power supply fast so I called Rowan. At first he did not want to talk with me. Then he realized that I was again a customer and warmed right up. I bought a 100kW Tri Line that Inductotherm has in stock for fast delivery.

Rowan was experimenting with a new capacitor that he could buy much cheaper. On startup every one of these capacitors blew up. It was less than a week before a service engineer flew in with new capacitors to get us on line.

Our fourth daughter was born in Gastonia, North Carolina. She had a birth defect in the tube that connects the intestine to the stomach. She was not able to withstand the operations required to repair the defect. The little girl never came home, so her death was not a problem for the other children.

The beryllium business went downhill fast. It was only a matter of time before this plant closed. Jody was very hurt with the death of her daughter. My decision to move may have been welcome at that time. This move in January 1965 was number nineteen for Jody in eleven years.

Ajax rehired me as their upstate New York salesman because they could find no one better to fill the position. We rented a house in Hamburg, New York. Jack Kemp, the quarterback of the Bills, and several other members of the team lived in our neighborhood. The two young boys kept Jody at wit's end by playing so near the turnpike. She could not understand that boys would always seek adventure in unsafe places. She found friends and we began to attend church on a regular basis. It was the time of the "God is dead" movement and I became a very active student in the new concept of religion. I started reading every philosophy book I could get my hands on starting with Descartes and ending with Einstein.

Ajax really wanted me back to finish the job at NASA. The chief engineer of Ajax traveled with me for the start up tests. He had designed the system to use four of his trick circuit transformers so we could keep the temperature uniform from to bottom of this monstrosity NASA had ordered. The transformers fought each other, and instead of producing the third harmonic of sixty-cycles they ran away and produced the ninth harmonic. Rowan later built a power supply using this principle that he called the "NineLine." This project never worked the way NASA wanted it to work. It was settled in the courts some years later.

My instructions were to make calls on every foundry in the territory to push the induction furnace. The problem was Ajax did not have the right equipment and the Europeans suppliers were eating us alive.

I fought hard and won a very important order from General Electric in 1965. The Inductotherm, Stokes combination should have won these order using pricing and superior induction coil designs. Rowan did not know it but the cards were stacked in this situation and I was positioned to draw three aces. First, Inductotherm used Westinghouse motor generators for their power supplies. Second, I was a melter and understood the process they planned to use to produce alloys for their gas turbines for electricity generation. Third, and most important, the president of Ajax had just put the future of his company on the line when he sold the largest induction heating system in the world. He needed GE's new SCR's to make this project work. GE wanted to use to test their new gadget they called SCR's. I was the melter and had the privilege to push the button on the first large solid state induction power supply. It was too early for a new type power supply because the production lines GE set up to produce these large SCR's had quality control problems and these gadgets were failing with regularity. Rugged reactors transformers would have to tickle and trick 60-cycle into becoming 180-cycle and 540-cycle for large induction power supplies a few more years.

Anaconda and the US government has almost 1000-tons of nickel-copper that was useless for the pipe work on ships and submarines because it was too high in carbon. Specifications were issued at the home office of Anaconda for a simple vacuum furnace to process this material.

Inductotherm had this order locked up before Ajax learned that a 10-ton furnace would be installed in Buffalo. I knew we could use copper oxide to reduce the carbon in vacuum. Test melts could were made at Firth Sterling to prove a vacuum/oxygen idea. It worked and Ajax won the order.

I did not win all the orders for vacuum melting during the Ajax days. Inductotherm in combination with Stokes obtained orders for the five ton class vacuum melting furnaces for customers to include Allvac, Eastern Stainless Steel, Special Metals, Wyman Gordon and Aubert et Duval.

In 1965 Allegheny Ludlum purchased the outstanding public stock of Special Metals to establish their steel company as the leader in the superalloy and specialized stainless steel business. The new owners wanted a furnace that could match or exceed the Carpenter Steel, Allvac, and Latrobe furnaces. Jack Huntington, Vice President of Engineering, now had funds and started looking for suppliers.

On March 17,1966 Armstrong and Scott attempted to dock their Gimini capsule with another spacecraft but failed. The Soviets had completed the first spacewalk months earlier.

In the early part of 1966 I was able to obtain the prize job for vacuum melting from Special Metals. http://www.ioa.com/~zero/394-SpecialMetals2.html

I was the total misfit at Ajax with projects that none of the engineers or bosses understood. Logan was preparing to go public and by putting his company on the American stock exchange. The $10 million dollar order he had accepted for the steel heating project in Detroit and my big order completely messed up the commission scheme that he had established to compensate his salesmen. He changed the rules on commissions for large jobs. Calculations were to stop above one million dollars.

I had a major investment of time and effort with a customer in Rochester. General Motors was in the process of upgrading and automating their carburetor production. It was difficult to convince the manager of the Ajaxomatic product line to redesign the equipment to meet all the new government specifications. The customer agreed that this was going to be expensive but agreed to pay $50,000 extra for the first furnace making the total order for 20 units in excess of $400,000. The purchasing agent agreed that I had worked hard for him and therefore found reasons to give me 20 purchase orders to maximize my commission.

I took that stack of orders to Logan's office before booking them into the system. He realized that this little order put me over the $4-million mark for the year and congratulated me on the commission I had earned on the GM job.

My little upstate New York territory had sales for Ajax that were about fifty percent of Inductotherm in 1966. The loss of extra income from the Special Metals job made me a little angry, but the loss of the ability to sell and control the product line really bothered me. I told Logan that I was going to become a consultant. His advice was that I also should find a niche and also offer a product to succeed in business.

The next vacuum furnace job in the USA was at Universal Cyclops for a furnace system twice as large as the one at Special Metals. I assisted Temescal with modifications to the Special Metals design to make it fit a 30-ton design. They agreed to let me handle the engineering and installation of this job when my business was established. They also agreed to hire me on a time and material basis to install the facility at Special Metals.

On January 1,1967 Industrial Service Enterprise was born, without detailed plans for the new venture. Our camping trailer was moved to Utica in order to live at the job site. My net worth at that time, according to my books, was $106.91. With five kids, a two year old Ford station wagon, a rented house, and future commissions from jobs already sold at Ajax, I was off on a new road.

Like Hank Rowan, I was never able to work for someone. In almost every situation in my life the driving force has been a great desire and drive to accomplish the task that was self-defined. Without the technical background to understand the details of the projects that attracted me, it was uncharted courses that were undertaken.

Building companies and new technologies requires a front man to act as the leader and catalyst to make the system work, despite the political or economic situation. I have always been an idea man. Most of them have been useless, but sometimes a very good idea came along.